Adastria manufactures products in various regions around the world with a complex and extensive supply chain, including raw material procurement, sewing, and transportation processes. We recognize that it is our corporate responsibility to collaborate and strengthen partnerships that focus on the sustainable development of production areas and the stable supply of high-quality products, striving to ensure continuous and good business practices with our business partners. Adastria strives to continue to provide our customers with better products and services. To this end, we not only comply with the laws and regulations of each country and region, but we also monitor and engage in procurement activities that enable fair and ethical transactions.

Group Sourcing Policy and Group Sourcing Guidelines

In partnership with our suppliers, we have established the Group Sourcing Policy, targeting fair and ethical business dealings unique to Adastria, and the Group Sourcing Guidelines, which clearly state our expectations in the areas of human rights, social, environmental, and governance. With these, we have gained the understanding of our suppliers that we expect them to be in compliance with certain areas.

List of Specified Partner Suppliers(As of September 2024)

The Adastria Group publishes its supplier list as part of its efforts to fulfill its corporate responsibility and improve the industry as a whole with regard to social issues such as environmental concerns and human rights issues. By making this list public, we aim to work with our suppliers to build a supply chain that is positive for the environment, people, and society, as well as to increase transparency and establish responsible production methods. In addition, we aim to increase the number of companies that agree with our management stance of increasing corporate value together with our partner suppliers, and to work toward resolving issues throughout the entire supply chain. The names, locations, and production types of the 47 companies with direct trade backgrounds are disclosed as a supplier list. Going forward, we will periodically review the list to expand and deepen the scope of disclosure and the information disclosed, as we strive to strengthen our partnership with suppliers through dialogue.

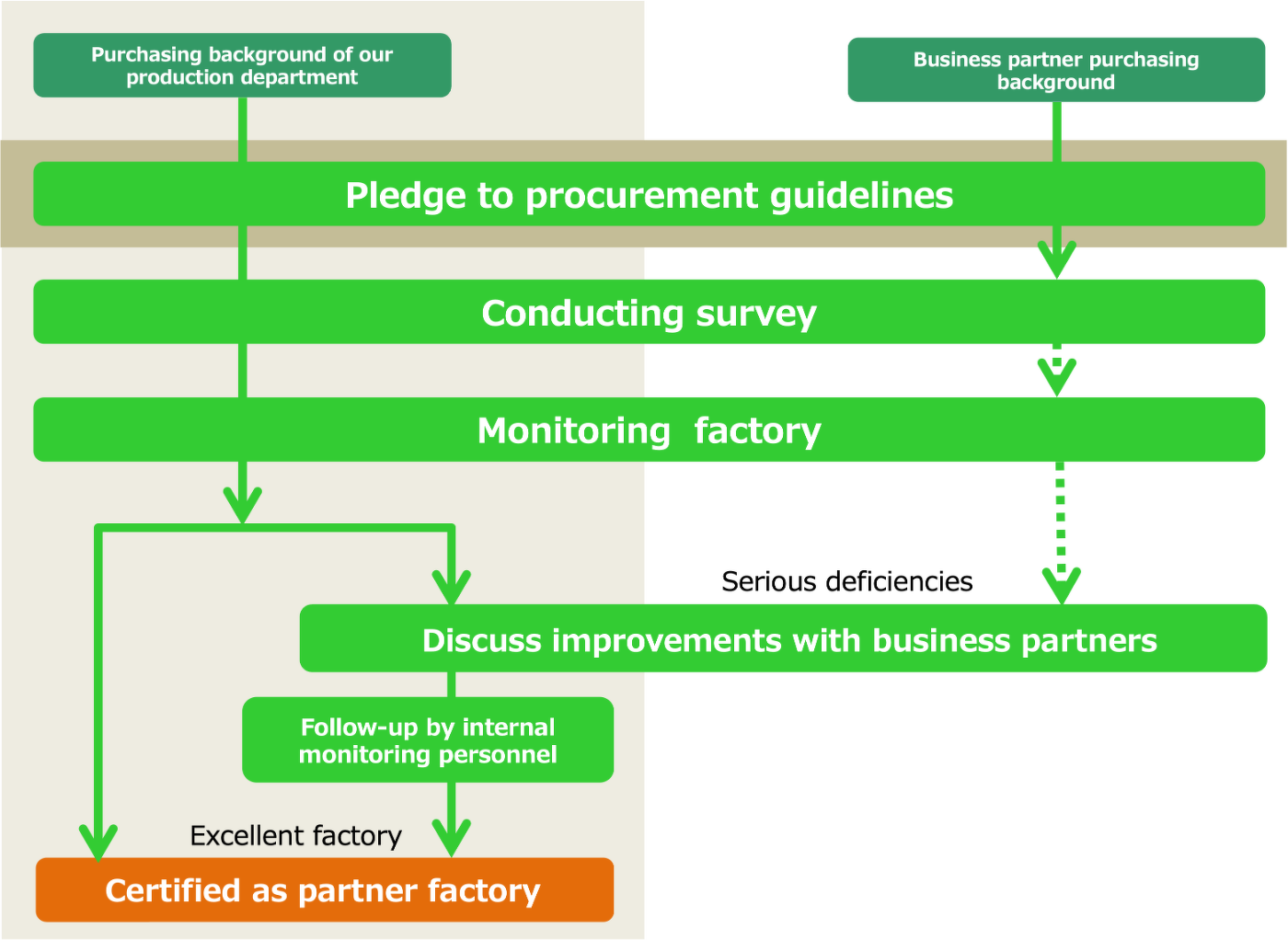

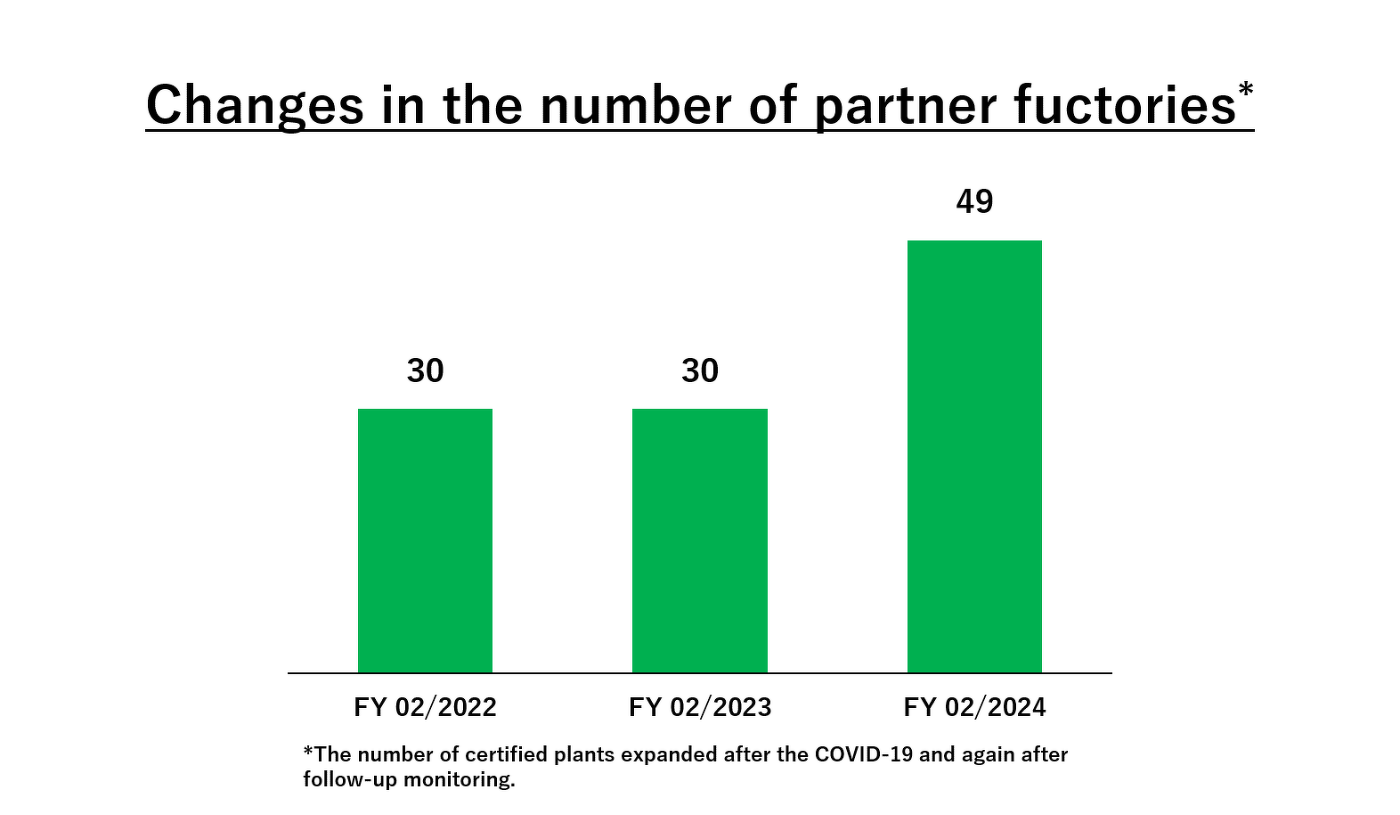

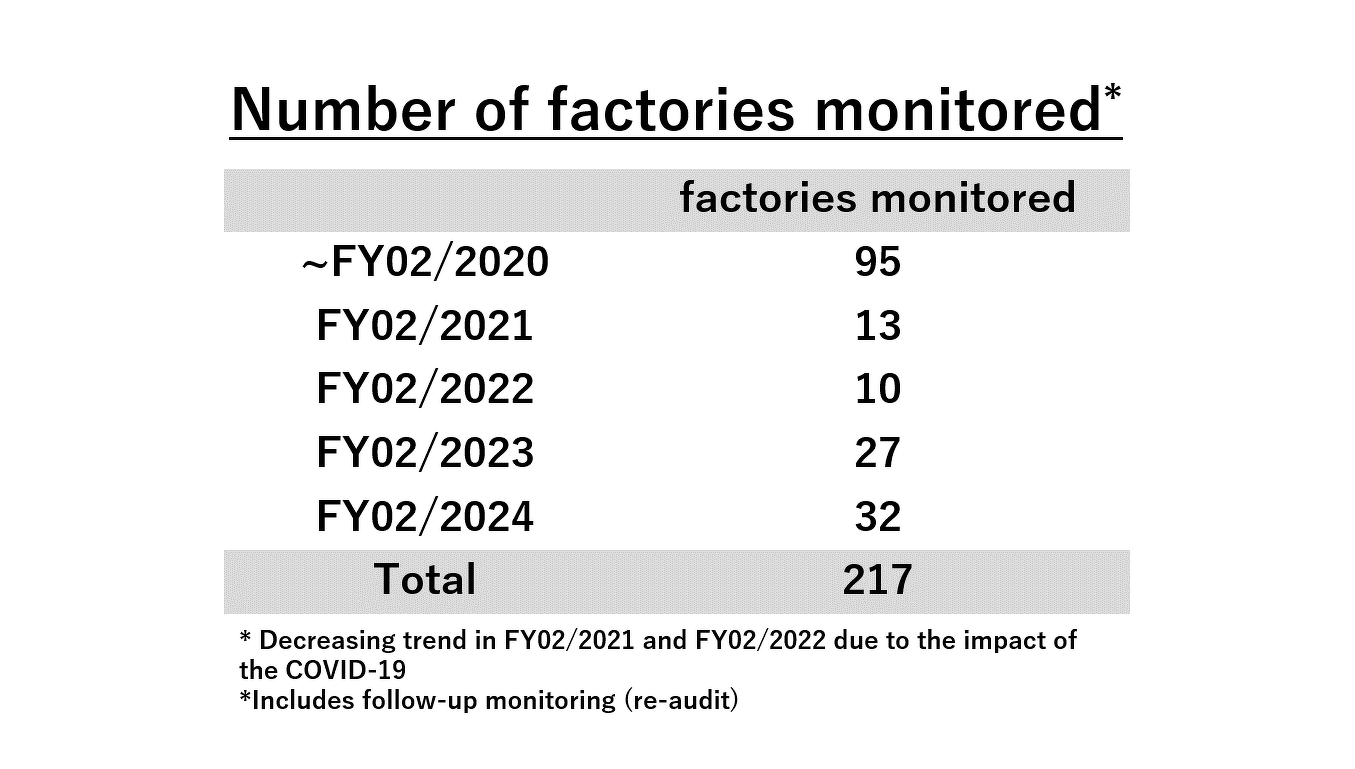

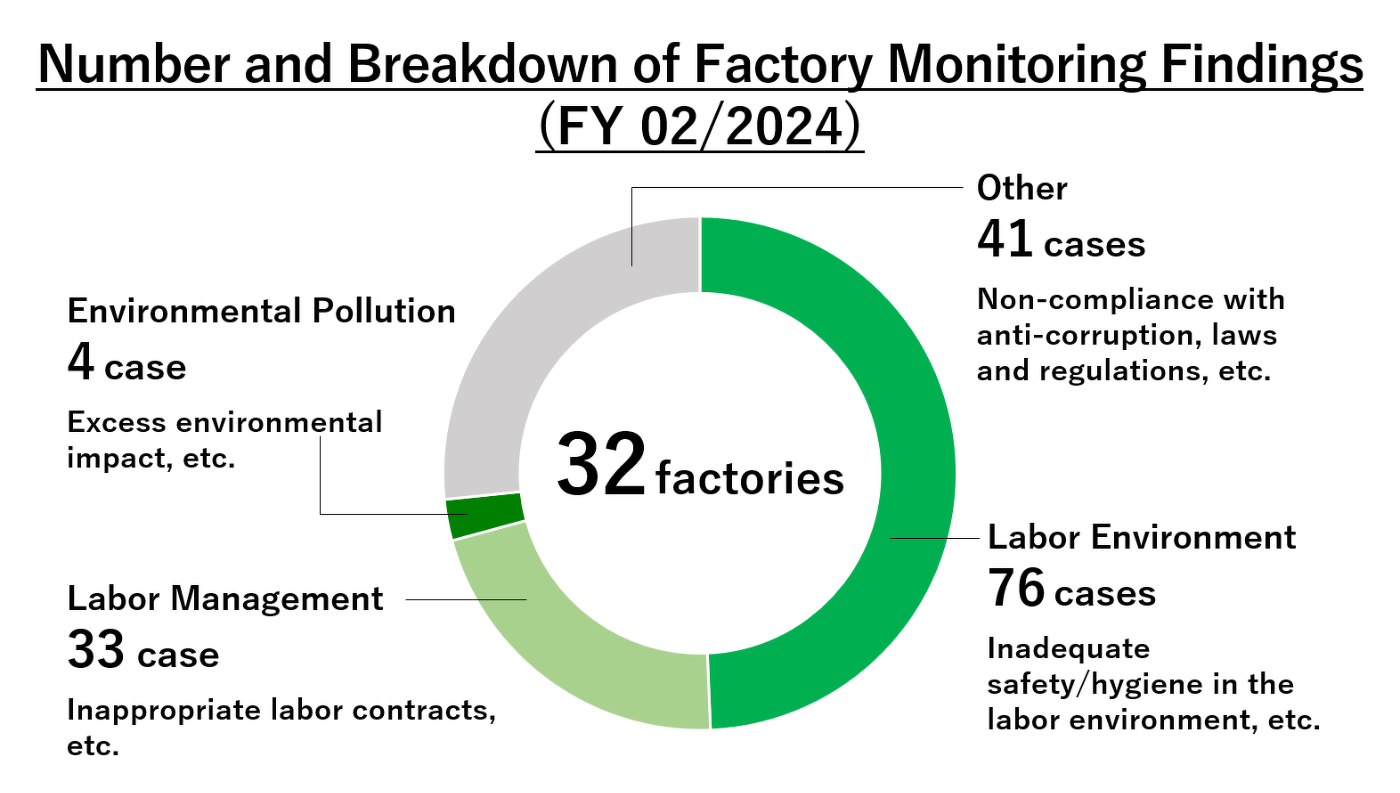

Factory Monitoring and Partnership Certification

Suppliers are asked to cooperate in compliance surveys based on our sourcing guidelines. Based on the results, our CSR procurement staff conduct factory monitoring to directly check the production environment. If any issues are identified for improvement, we ask the supplier in question to make improvements based on direct and ongoing interactions, leading to stronger engagements. We have a system in place to certify suppliers working with our production departments as partner factories, based on a comprehensive scrutiny of their systems for producing high-quality products, frequency of product defects, and social, environmental, and governance conditions. Going forward, we will continue to expand both the number of partner-certified factories and the number of factories monitored.

Contributing to Local Human Resource Development Through a Centralized Production Management System

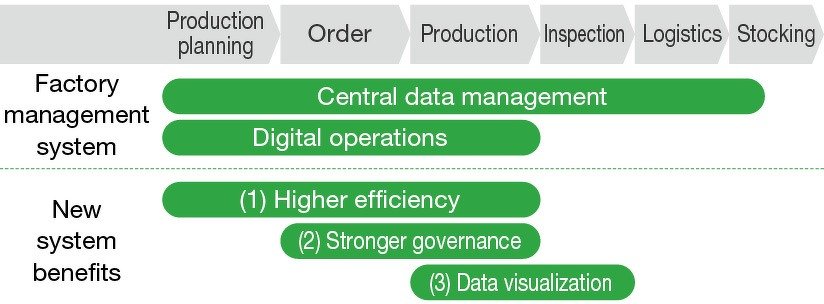

We have implemented a new factory management system to centralize product ordering for our factories and production control data. Until now, progression along each supply chain and the status of each factory were managed separately, but this new system offers digital order and production management operations and centralized management and system integration from production planning to purchase accounting along the value chain. With these upgrades, we can not only improve work efficiency both for internal and external stakeholders, but we can also help prevent human error and strengthen governance. Particularly in working with local staff in China and ASEAN countries, our main production areas, it would take quite some time to check information before we introduced this system. The new system has also contributed to human resource development, as seen in the improved digital skills among local staff.

Back to Materialities and Targets